ASTM A519 Cold Finished Mild Steel Tubing , Thin Wall Alloy Steel Mechanical Tube With API

ASTM A519 Cold finished Mild Steel Tubing , Thin Wall Alloy Steel Mechanical Tube with API

Product Description

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required.

Product | Mild Steel Tubing | |||

Wall thickness | 1MM~12MM | |||

Outer Diameter | 20MM~508MM | |||

Physical Property | API 5L, ASTM A519, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996,

ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |||

Application | Conveying oil gas and water | |||

Surface Treatment | Bare,Painting black,varnished,galvanized,anti-corrosion 3PE

PP/EP/FBE coating | |||

Grade | SPCC,SPCD,SPCE,ST12-15,DC01-06,Q195A-Q235A,Q195AF-Q235AF, Q295A(B)-Q345A(B) | |||

Standards | AISI ASTM JIS SUS DIN GB | |||

Certifications | CE,AS4020,BSI,ANAB,ISO9001 | |||

Packing | Industry standard packaging or according to client's requirement | |||

Brand | TISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO,HXSCO, Chengde,Yongjin,Tsingshan,Shouyang,HW | |||

Payment | T/T,L/C,Western Union,Paypal,Apple Pay,Google Pay,D/A,D/P,MoneyGram | |||

Delivery time | Up to order quantity | |||

Grade and Chemical Composition (%) of ASTM A519:

Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

ASTM A519 1008 | ≤0.10 | 0.30-0.50 | 0.04 | 0.05 | - | - | - |

ASTM A519 1010 | 0.08-0.13 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

ASTM A519 1015 | 0.13-0.18 | 0.30-0.60 | 0.04 | 0.05 | |||

ASTM A519 1018 | 0.15-0.20 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

ASTM A519 1020 | 0.18-0.23 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

ASTM A519 1025 | 0.22-0.28 | 0.30-0.60 | 0.04 | 0.05 | - | - | - |

ASTM A519 1035 | 0.32-0.38 | 0.60-0.90 | 0.04 | 0.05 | |||

ASTM A519 1045 | 0.43-0.50 | 0.60-0.90 | 0.04 | 0.05 | |||

ASTM A519 1026 | 0.22-0.28 | 0.60-0.90 | 0.04 | 0.05 | - | - | - |

ASTM A519 4130 | 0.28-0.33 | 0.40-0.60 | 0.04 | 0.04 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

ASTM A519 4140 | 0.38-0.43 | 0.75-1.00 | 0.04 | 0.04 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties of ASTM A519:

Grade | Condition | Ultimate Strength | Yield Strength | Elongation | Rockwell Hardness | ||

Ksi | Mpa | Ksi | Mpa | % | B scale | ||

ASTM A519 1020 | HR | 50 | 345 | 32 | 221 | 25 | 55 |

CW | 70 | 483 | 60 | 414 | 5 | 75 | |

SR | 65 | 448 | 50 | 345 | 10 | 72 | |

A | 48 | 331 | 28 | 193 | 30 | 50 | |

N | 55 | 379 | 34 | 234 | 22 | 60 | |

ASTM A519 1025 | HR | 55 | 379 | 35 | 241 | 25 | 60 |

CW | 75 | 517 | 65 | 448 | 5 | 80 | |

SR | 70 | 483 | 55 | 379 | 8 | 75 | |

A | 53 | 365 | 30 | 207 | 25 | 57 | |

N | 55 | 379 | 36 | 248 | 22 | 60 | |

ASTM A519 1035 | HR | 65 | 448 | 40 | 276 | 20 | 72 |

CW | 85 | 586 | 75 | 517 | 5 | 88 | |

SR | 75 | 517 | 65 | 448 | 8 | 80 | |

A | 60 | 414 | 33 | 228 | 25 | 67 | |

N | 65 | 448 | 40 | 276 | 20 | 72 | |

ASTM A519 1045 | HR | 75 | 517 | 45 | 310 | 15 | 80 |

CW | 90 | 621 | 80 | 552 | 5 | 90 | |

SR | 80 | 552 | 70 | 483 | 8 | 85 | |

A | 65 | 448 | 35 | 241 | 20 | 72 | |

N | 75 | 517 | 48 | 331 | 15 | 80 | |

ASTM A519 4130 | HR | 90 | 621 | 70 | 483 | 20 | 89 |

SR | 105 | 724 | 85 | 586 | 10 | 95 | |

A | 75 | 517 | 55 | 379 | 30 | 81 | |

N | 90 | 621 | 60 | 414 | 20 | 89 | |

ASTM A519 4140 | HR | 120 | 855 | 90 | 310 | 15 | 100 |

SR | 120 | 855 | 100 | 689 | 10 | 100 | |

A | 80 | 552 | 60 | 414 | 25 | 85 | |

N | 120 | 855 | 90 | 621 | 20 | 100 | |

Tube Designation:

Designation | Symbol | Description |

Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming. (e.g. bending, expanding). |

Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

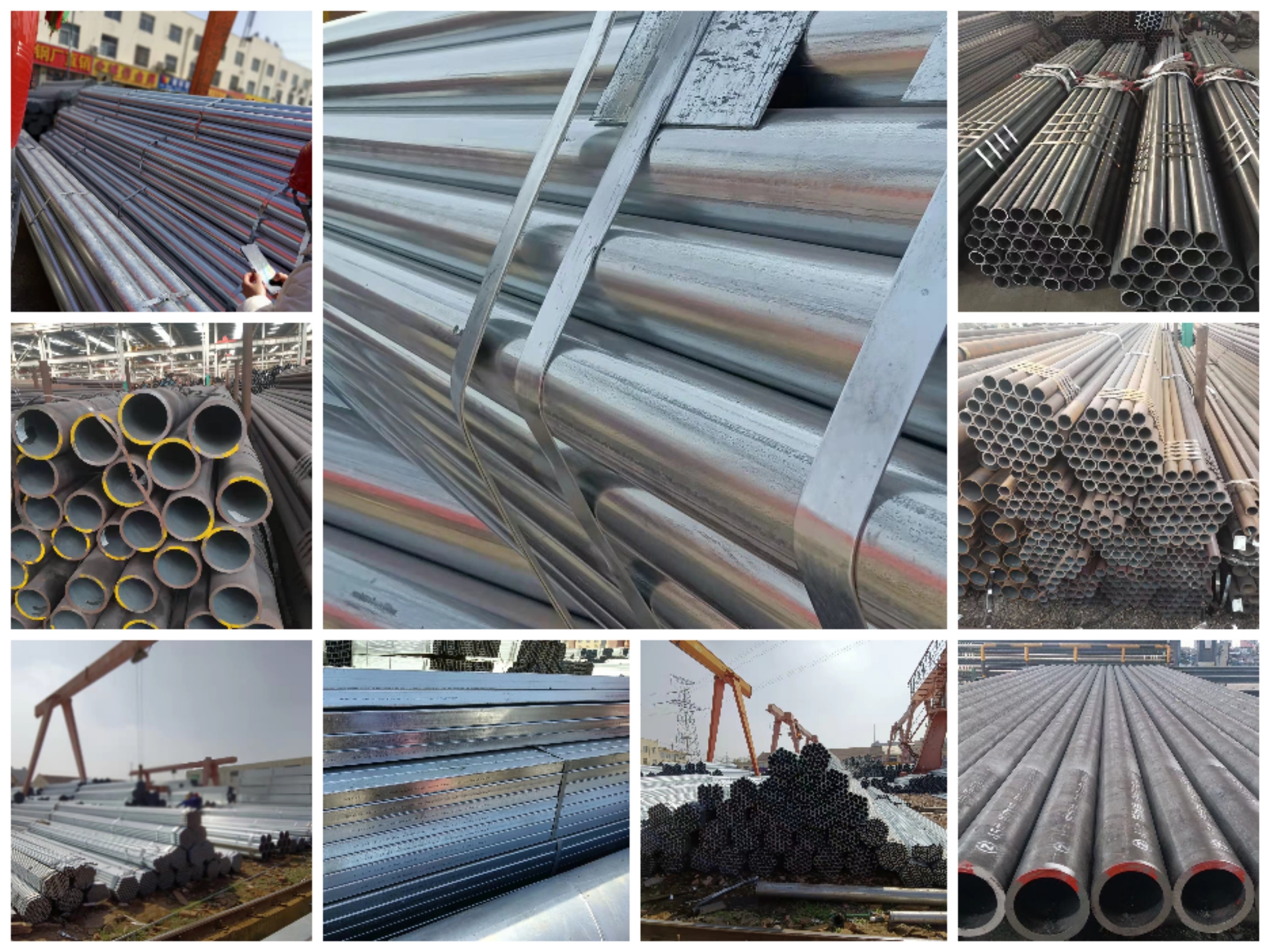

Detailed Photo:

Factroy Pictures:

Pipe & Tube Processing:

Steel Pipe & Tube Application:

Packaging and Shipping:

Certificates:

FAQ:

Q1: ARE YOU FACTORY OR TRADER?

A1: Wuxi Sylaith Special Steel Co.,Ltd is a manufacturer of steel

pipe and tube since 2010. We've gained our Export Right and become

an integrated company of industry and trade in order to satisfy

buyer's multi-request on different material and products.

Q2: WHICH MATERIAL/PRODUCTS YOU CAN PROVIDE?

A2: Seamless Stainless Steel Pipe / Tube, Seamless Carbon Stainless

Steel Pipe /Tube,Galvanized Steel Tube witn any Shape and Welded

pipes can also be available.

Q3: HOW TO GET A SAMPLE?

A3: FREE samples are available for your checking and testing. And

to get free samples, you need to send us you detailed receiving

address (including post code) and your DHL/FedEx/UPS account for

collecting samples, courier cost will be paid in your side.

Q4:CAN YOU PRODUCE THE PRODUCTS ACCORDING TO MY OWN DRAWINGS?

A4: Yes, we can produce the products according to your drawings

that will be most satisfy you.

Q5: HOW TO VISIT YOUR FACTORY?

A5: Most of the main cities have flights to Shanghai; you can take

flight to Shanghai Putong/Hongqiao International Airport.

If you come from Hongkong, it will take 2 hours by flight (every

day 5 flight around noon time).

WUXI SYLAITH SPECIAL STEEL CO.,LTD

Wuxi Sylaith Special Steel Co.,Ltd

Wuxi Sylaith Special Steel Co.,Ltd has 20,000 square meters of indoor storage, more than 20,000 tons of spot inventory. spot product standard involves european standard, american standard, british standard, australian standard, german standard, russian standard, japanese standard, national standard and so on.

Since its establishment, Wuxi Sylaith Special Steel Co.,Ltd has gained rich experience in Pipes, Fittings, Flanges, Valves, Structural steel, Coils and Plates in past twenty years. And our company has expanded its field of activities and entered in trade and supply of tubular & flat products in Duxplex and Super Duplex, Stainless Steel, Nickel Base alloy Steel ,Cr-Mo alloy steel , Copper Nickel alloy steel,Carbon Steel for our reputed clients worldwide. The products cover steel structure engineering, nuclear power engineering, ocean engineering, construction and bridge engineering, construction machinery and equipment production, metallurgical equipment production and other fields.

Wuxi Sylaith Special Steel Co.,Ltd adheres to the distribution strategy of multiple varieties, direct supply and nearest matching. In the future the company will, as always adhering to the "customer as the buddha, are proud of the service" business philosophy, adhere to the "create, win-win" spirit of enterprise, adherence to the "first-class service, first-class products, a comprehensive build the company's core competitiveness, to provide the most valuable industry services, is committed to become china's best solution steel sales company.