ASTM B633-07 Annealed Galvanized Steel Tube , Thin Wall Cold Drawing E355 Steel Pipe

ASTM B633-07 Annealed Galvanized Steel Tube , Thin Wall Cold

Drawing E355 Steel Pipe

Application areas: Automotive, military, railway industry, with

high requirement of the tubes brightness, cleanness, antirust, and

antisepsis.

Product Name | Galvanized Steel Tube |

Material | 10#, 20#, 45#, 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42,

St37-2, St35.4, St52.4, ST35 |

Wall Thickness | 1.4-14mm or as required |

Outer Diameter | 20mm~508mm or as required |

Length | Length:Single random length/Double random length 5m-14m,5.8m,6m,10m-12m,12m or as customer's actual requirements |

Standard | API 5L, ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM

A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296,

BS 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992,

GB/T9711 |

Grade | 10#-45#, 16Mn, A53-A369, Q195-Q345, ST35-ST52 Grade A, Grade B, Grade C |

Technique | Hot Dip Galvanized Round Steel Pipe |

Packing | Standard SeaWorthy Package or as your requirements |

Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut

quare,grooved,threaded and coupling,etc. |

Surface Treatment | 1. Galvanized 2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

Product Application | 1. Fence, greenhouse, door pipe,greenhouse 2. Low pressure liquid, water, gas, oil, line pipe 3. For both indoor and outdoor the building construction 4. Widely used in scaffolding construction which is much cheaper and convenient |

Origin | Shinghai China |

Certificates | API ISO9001-2008,SGS.BV |

Delivery Time | Usually within 7-10 days after receipt of advance payment |

Dimensions of the galvanized tubes for hydraulic and pneumatic

lines

Outside diameter ranges from 6 to 350 mm and the wall thickness

ranges from 0.8 to 30 mm.

Precision steel tubes are delivered according to EN 10305-4, DIN

2391-1, STN 42 6711 and 42 6712, ČSN 42 6711 and 42 6712.

Synopsis of Process Routing

DIN highly accurate cold drawn bright seamless steel tube is used

as the tube to be galvanized, the outer wall is electroplated, caps

are covered at two ends of tube to prevent from the dust.

Main Features

Different color of zinc such as white, yellow, army-green, black is

evenly distributed in the surface of the tube, good brightness and

antirust and antisepsis could improve after zinc coated.

Length of the galvanized tubes

in diameter <= 16 mm >=6000 + 100 mm

in diameter >= 16 mm <=24000 + 50 mm

Tolerances of the zinc coated tubes

- tolerances of the outside diameter:

diameter between 4 - 30 mm | ±0,08 mm |

diameter between 35 - 38 mm | ±0,15 mm |

diameter above 42 mm | ±0,20 mm |

- tolerances of the inside diameter are according to EN 10305-4

- tolerance of the wall thickness ± 10%

Grade and Chemical Composition(%)

Grade | Chemical Composition(%): | ||||

C max | Si max | Mn | P max | S max | |

E355 | 0.22 | 0.55 | 1.6 | 0.025 | 0.025 |

E235 | 0.17 | 0.35 | 1.2 | 0.025 | 0.025 |

E215 | 0.10 | 0.05 | 0.70 | 0.025 | 0.025 |

Mechanical Properties (Mpa)

Grade | Yield strengtha Rehmin Mpa | Tensile strengtha Rmmin Mpa | Elongation A min % |

E215 | 215 | 290-430 | 30 |

E235 | 235 | 340-480 | 25 |

E355 | 355 | 490-630 | 22 |

Final supply conditions

Designation | Symbol | Description |

Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Galvanized tube category and related standard

Galvanized tube category and related standard | |||

Galvanized tube category | Related Standard | Zinc coating thickness | Salt spray test |

Gr3+ Galvanized tube with blue and white zinc | ASTM B633-07 | 5-25um | 24--72 hours without white rust;48--168 hours without red rust |

Gr3+ Galvanized tube with color zinc | ASTM B633-07 | 5-25um | 48--96 hours without white rust;48--240 hours without red rust |

Gr6+ Galvanized tube with color zinc | ASTM B633-98 | 5-25um | 24--96 hours without white rust;48--124 hours without red rust |

Applications

Zinc coated precision steel tubes (galvanized tubes) are destined

for hydraulic and pneumatic pressure distribution (so called HPL

tubes), production of automobile components, utility vehicles as

well as for production of machine products such as fittings and

joints. Cold drawn precision tubes are used as the semi-finished

product and they are made from rolled seamless tubes. Precision

tubes HPL types are made from carbon and alloyed steel.

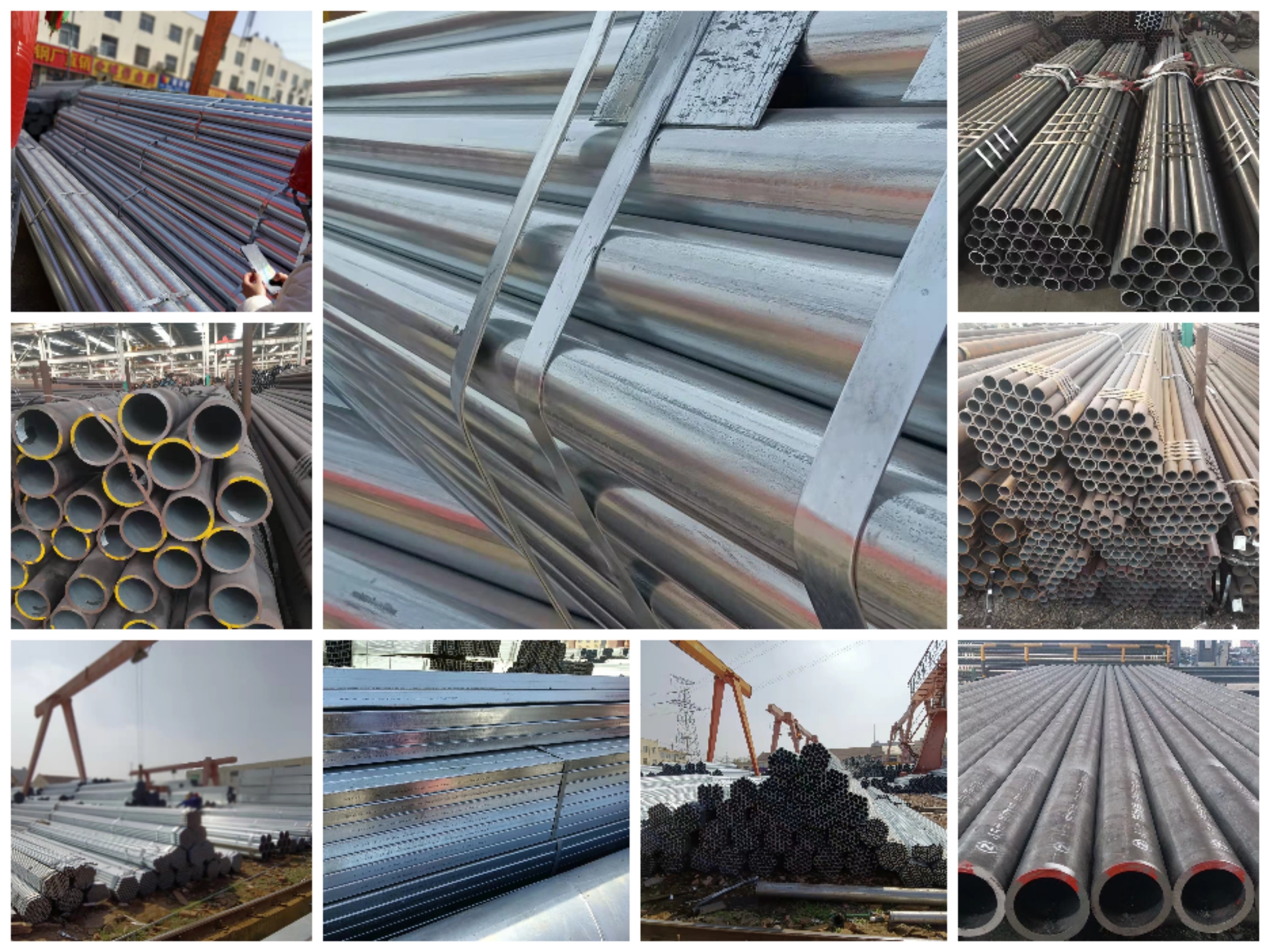

Product Photo

Factroy Pictures

Pipe & Tube Processing

Application

Packaging & Shippping

Certificates

FAQ

Q1: ARE YOU FACTORY OR TRADER?

A1: Wuxi Sylaith Special Steel Co.,Ltd is a manufacturer of steel

pipe and tube since 2010.

We've gained our Export Right and become an integrated company of

industry and trade in

order to satisfy buyer's multi-request on different material and

products.

Q2: WHICH MATERIAL/PRODUCTS YOU CAN PROVIDE?

A2: Seamless Stainless Steel Pipe / Tube, Seamless Carbon Stainless

Steel Pipe /Tube,

Galvanized Steel Tube witn any Shape and Welded pipes can also be

available.

Q3: HOW TO GET A SAMPLE?

A3: FREE samples are available for your checking and testing. And

to get free samples,

you need to send us you detailed receiving address (including post

code) and your

DHL/FedEx/UPS account for collecting samples, courier cost will be

paid in your side.

Q4: CAN YOU PRODUCE THE PRODUCTS ACCORDING TO MY OWN DRAWINGS?

A4: Yes, we can produce the products according to your drawings

that will be most satisfy you.

Q5: HOW TO VISIT YOUR FACTORY?

A5: Most of the main cities have flights to Shanghai; you can take

flight to Shanghai Putong/Hongqiao International Airport.

If you come from Hongkong, it will take 2 hours by flight (every

day 5 flight around noon time).

WUXI SYLAITH SPECIAL STEEL CO.,LTD

Wuxi Sylaith Special Steel Co.,Ltd

Wuxi Sylaith Special Steel Co.,Ltd has 20,000 square meters of indoor storage, more than 20,000 tons of spot inventory. spot product standard involves european standard, american standard, british standard, australian standard, german standard, russian standard, japanese standard, national standard and so on.

Since its establishment, Wuxi Sylaith Special Steel Co.,Ltd has gained rich experience in Pipes, Fittings, Flanges, Valves, Structural steel, Coils and Plates in past twenty years. And our company has expanded its field of activities and entered in trade and supply of tubular & flat products in Duxplex and Super Duplex, Stainless Steel, Nickel Base alloy Steel ,Cr-Mo alloy steel , Copper Nickel alloy steel,Carbon Steel for our reputed clients worldwide. The products cover steel structure engineering, nuclear power engineering, ocean engineering, construction and bridge engineering, construction machinery and equipment production, metallurgical equipment production and other fields.

Wuxi Sylaith Special Steel Co.,Ltd adheres to the distribution strategy of multiple varieties, direct supply and nearest matching. In the future the company will, as always adhering to the "customer as the buddha, are proud of the service" business philosophy, adhere to the "create, win-win" spirit of enterprise, adherence to the "first-class service, first-class products, a comprehensive build the company's core competitiveness, to provide the most valuable industry services, is committed to become china's best solution steel sales company.